Why Oil Return Fails in Long-Line Freon Systems — And How to Fix It

- KGM DaVinci

- Oct 5, 2025

- 3 min read

Introduction

Oil return is one of the most misunderstood — and most costly — failure points in Freon compressor rack systems. Whether you're installing in a cold store in Morocco or a logistics hub in Dubai, long suction lines and poor pipe design can quietly sabotage your system.

At KGM Refrigeration, we’ve seen it firsthand: compressors damaged, efficiency lost, and installers blamed — all due to oil that never made it home.

This post breaks down the physics of oil return, the common design mistakes, and how contractors can fix or prevent them — with a special focus on oil types used in MENA climates.

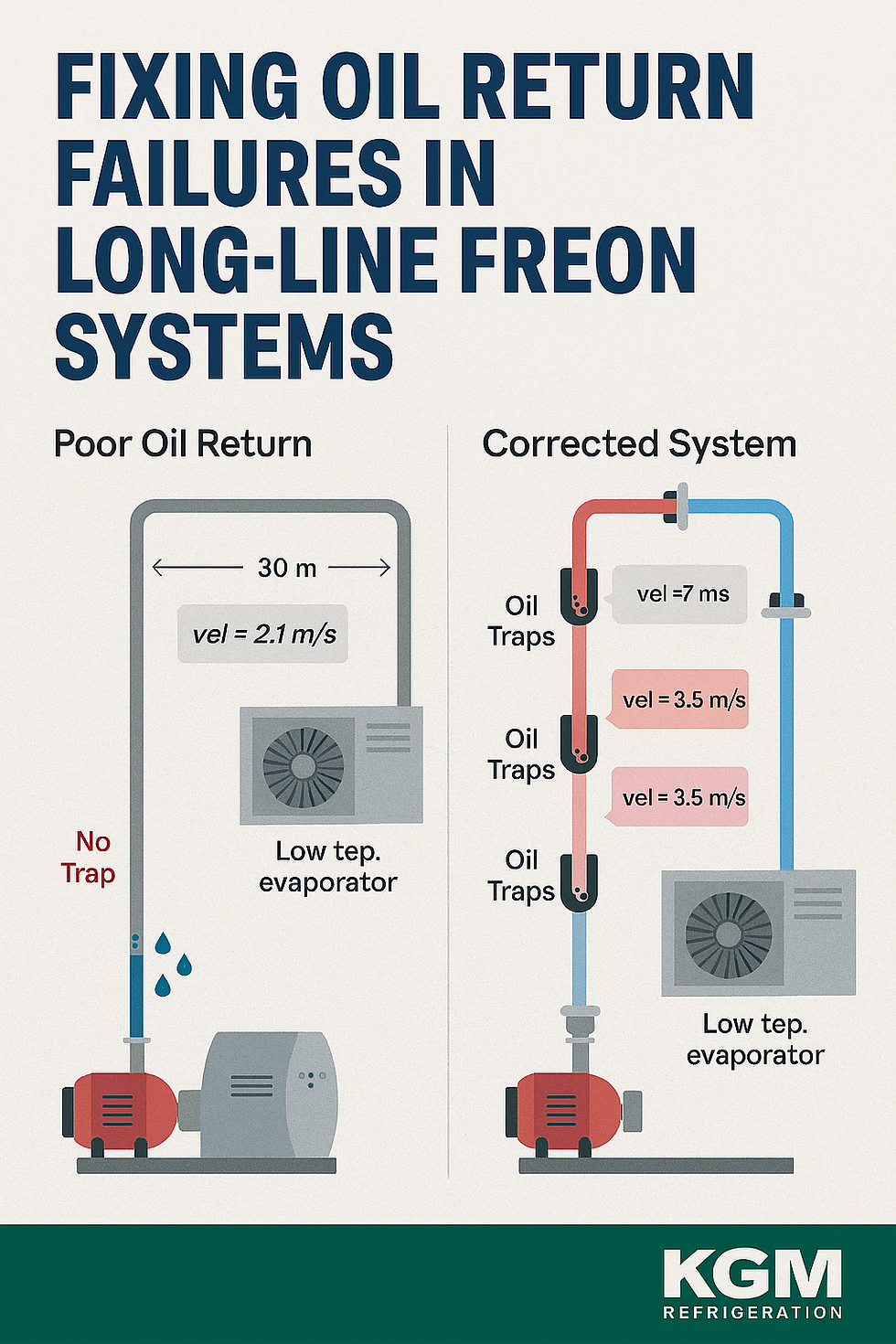

1.The Physics of Oil Return: It’s All About Velocity

Oil doesn’t flow like refrigerant. It needs to be entrained — carried by vapor flow at a minimum velocity.

🔬 Key Thresholds:

Horizontal suction lines:

Minimum velocity ≈ 3.5 m/s

Vertical risers:

Minimum velocity ≈ 7 m/s

Below these thresholds, oil separates from vapor and settles in the pipe — leading to pooling, slugging, and compressor starvation.

2. Oil Types in Freon Systems — What MENA Contractors Need to Know

Choosing the right oil is critical for proper return, especially in high ambient and long-line systems typical in the Middle East.

🔹 Mineral Oil (MO)

Used with older Freon blends like R-22

Low solubility with refrigerant → poor oil return in long lines

Not recommended for modern HFC systems

🔹 Alkylbenzene (AB)

Better solubility than MO

Often used with R-22 and R-407C

Performs well in moderate ambient but struggles in extreme heat

🔹 Polyolester (POE)

Standard for HFCs like R-134a, R-404A, R-507

High solubility with refrigerant → better entrainment

Sensitive to moisture → requires tight evacuation and filtration

Common in MENA installations with R-404A racks

🔹 Polyvinyl Ether (PVE)

Used in select OEM systems with R-410A

Excellent thermal stability

Less common in MENA due to cost and availability

🔹 Synthetic Blends (OEM-Specific)

Some compressor manufacturers use proprietary blends for better oil return and thermal stability

Especially relevant in high-load, rooftop installations in UAE, Saudi Arabia, and Oman

⚠️ Oil Return Challenges in MENA:

High ambient temperatures reduce refrigerant density → lower vapor velocity

Long suction lines and rooftop units increase oil pooling risk

POE oils can degrade if moisture isn’t properly evacuated

AB oils may struggle in systems with frequent cycling or partial load

KGM Tip: Always match oil type to refrigerant, ambient conditions, and pipe layout. For R-404A systems in MENA, POE oils with proper filtration and velocity-based pipe design offer the best reliability.

3. Why Long Lines Make It Worse

In large facilities, suction lines can stretch 30–50 meters or more. That’s where the problems begin:

Oversized pipes → lower velocity

Multiple evaporators → uneven loading

Flat routing → poor slope and pooling

Elbows and tees → turbulence and oil traps

Even if the system runs fine at full load, part-load conditions often drop velocity below safe limits.

4. Common Design Mistakes

❌ Mistake 1: Pipe sizing based on pressure drop only

Ignoring velocity leads to oversized suction lines.

❌ Mistake 2: No oil traps in vertical risers

Oil falls back during off cycles, causing slugging on restart.

❌ Mistake 3: No slope in horizontal runs

Flat pipes = oil puddles = compressor damage.

❌ Mistake 4: No velocity map during design

Designers rarely calculate actual vapor speed — installers pay the price.

5. How to Fix It (Or Prevent It)

✅ Use velocity-based pipe sizing

Calculate vapor velocity at full and part load. Resize suction lines if needed.

✅ Add oil traps in vertical risers

Use U-traps every 3 meters of rise — especially in multi-level systems.

✅ Maintain slope in horizontal runs

Minimum 1% slope toward compressor. More if ambient is cold.

✅ Balance evaporator loading

Avoid starving one circuit while overfeeding another — it affects vapor flow and oil entrainment.

✅ Use oil separators and return lines

In large racks, dedicated oil return systems are essential.

📈 Real-World Example: Cold Store in UAE

A Freon rack serving 12 evaporators across 60 meters of suction piping had recurring compressor failures. After analysis:

Suction velocity at part load was 2.1 m/s

No traps in 5-meter vertical riser

POE oil used without proper filtration

Oil pooled in flat horizontal run

Fixes:

Resized suction line

Added traps

Installed oil separator with timed return

Upgraded to moisture-tolerant POE variant

Result:Compressor life extended, no failures in 18 months.

🔗 Conclusion

Oil return isn’t just a design detail — it’s a system lifeline. If you’re installing or troubleshooting Freon racks in Europe or MENA, velocity matters — and so does oil type.

At KGM, we help contractors design smarter — with regional experience, and product configurations that match the realities of the field.

Comments